Corpus Christi Army Depot

MEASURING UP: CCAD ADOPTS ADVANCED

COMMISSIONING TECHNOLOGY SYSTEM

When it came to energy consumption as a naval installation tenant, the Corpus Christi Army Depot had no way of monitoring their machinery’s usage rates. That data had to come from the Navy through their main feeder, and even these usage rates were assumed.

“There was no way of real-time keeping track of how any of our major pieces of equipment were operating,” said Sean Dust, Mechanical Engineer of S4, Infrastructure Operations. He says they had no visibility of some of their most critical equipment like chillers, boilers and air handlers.

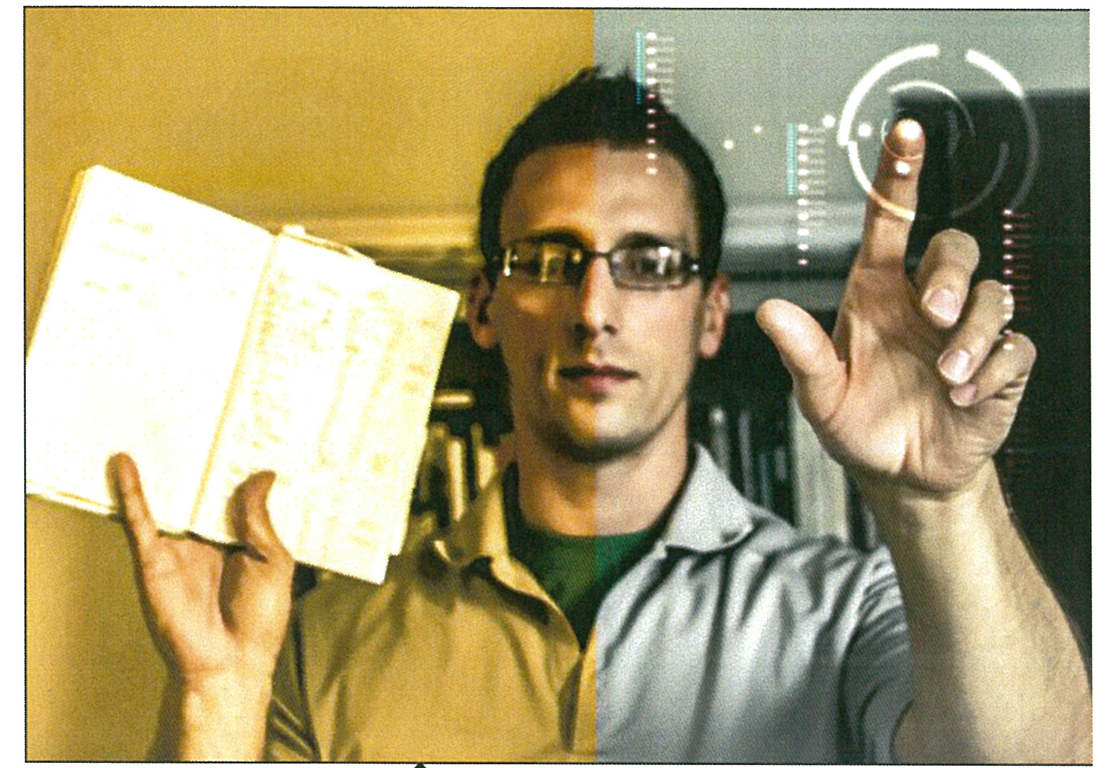

The only visibility they had was through aged military log books (only available in a few mechanical rooms) filled with (often inaccurate) numbers. This way of recording usage data was far from efficient, outdated and it inhibited analysis.

In the wake of a mandate by the government to reduce energy consumption 30% by 2015, S4 implemented and Advanced Commissioning Technology system. This software is the first of its kind in the DoD environment. Although still in its infancy stage of implementation, the potential of this software is big.

S4 now has a way to affect cost-wise readiness on the machines they employ every day. They can monitor in real-time operability, enabling proactive rather than reactive repair. The system also pulls data from the machines to let technicians know when they need maintenance, eliminating arbitrary and predetermined maintenance schedules. The mode even provides cost-benefit analysis on equipment, showing specifications side-by-side with a brand new model’s specs to show how much energy CCAD would save and the payback time. S4 will be able to see if the new machines are operating at optimal levels of efficiency.

Early success of the depot’s new software can be seen in the case of three of their boiler systems. The old way of thinking dictated that it was economically sound to run all three boilers simultaneously. If one boiler went down, then the other two would be there to provide what production needs.

“with [Advanced Commissioning Technology], it told us what this thinking was not completely correct on our part,” explained Dust. ”Yes, we want to have boilers in queue in case one fails, but we need all three running”

Marc Gonzalez, Director of S4 elaborated: ”Having the three boilers on was costing us a whole lot of money and we were only operating at 30% efficiency with three boilers on.”

Strategy shifted. Now, only one boiler is kept on with the second set up as a backup and the third shut off. ”We’re actually still producing what production needs but we’re saving whole lot of money,” said Gonzalez.

As it is still early in Advanced Commissioning Technology’s run at the depot, these three boilers are the only ones that are united with the system. ”The plan is to have hundreds of pieces of equipment tied in to this software within a year and half ,” said Gonzalez. ”The main effect is that we’re going to have a whole lot of cost savings. And the better part for our CCAD employees is that we’ll have less unscheduled downtime.”

The software is getting some attention from the Navy. They’re considering Advanced Commissioning Technology for some of their installation and, since the depot resides as a tenant of the Naval Air Station (NAS) Corpus Christi, CCAD is working with them with diagnostics and the prognostics for the entire base.